1. Executive Summary

This report examines Shoei’s recently filed patent for a novel modular helmet design, focusing on its innovative approach to seamlessly integrating the chin guard and face shield with the main helmet shell. The design directly addresses long-standing compromises inherent in modular helmet architecture, which often manifest as bulky hinges, visible seams, and awkward angles.

The patent claims significant benefits, including enhanced aerodynamics, improved impact force dispersion, and streamlined manufacturing processes. This strategic refinement by Shoei is poised to redefine expectations within the premium modular helmet segment, offering a more aesthetically pleasing, safer, and potentially quieter riding experience. The development underscores a broader industry trend towards perfecting existing technologies and elevating the overall user experience through meticulous design and engineering.

2. Introduction: The Evolution and Appeal of Modular Helmets

2.1. Brief History and Market Growth of Modular Helmets

The journey of motorcycle helmet development began in the early 20th century, driven by a growing recognition of the need for rider protection. Initial forms of head protection, such as shellacked canvas helmets, were first commissioned in 1914 by British physician Dr. Eric Gardner. These rudimentary helmets were notably mandated for racing events like the Isle of Man TT, significantly reducing head concussions among participants.1 Despite their demonstrated utility, civilian adoption was initially slow, with many riders preferring simpler padded leather caps for their aesthetic appeal over more protective, yet unconventional, designs.1

A pivotal moment arrived in 1935 with the tragic death of T.E. Lawrence, a British national hero, in a motorcycle accident. This event spurred Dr. Hugh Cairns to conduct extensive research into the correlation between motorcycle accidents and head injuries, leading to a British Army mandate for rubber and cork helmets for its dispatch riders.1

This period highlights a recurring pattern in helmet safety advancements: significant leaps often follow catastrophic events and subsequent regulatory interventions. This suggests that safety innovations are not solely market-driven but also emerge as a direct response to public health concerns and governmental directives.

Further revolutionary strides occurred in 1953 when C.F. Lombard developed the first truly impact-absorbing helmet, featuring a multi-layered construction with a hard fiberglass outer shell, an energy-absorbing foam middle layer, and a comfortable inner liner. This groundbreaking design was successfully commercialized by Bell Helmets with their Bell 500 model.1 Bell continued to innovate, introducing the first full-face motorcycle helmet, the Bell Star, in 1963, which offered unprecedented comprehensive protection.1 The establishment of the first U.S. Department of Transportation (USDOT) safety standards in 1964 and the subsequent US Highway Safety Act of 1966 further accelerated the widespread adoption and continuous improvement of helmet safety.1

Modular helmets, designed to combine the comprehensive protection of a full-face helmet with the convenience of an open-face configuration, first emerged in the 1970s and 1980s.1 This “Swiss Army knife” versatility, allowing riders to easily switch between modes, has driven an explosion in their popularity, particularly among touring riders, commuters, and those who prioritize convenience on the road . Modern helmets continue to evolve, integrating advanced composite materials like carbon fiber and Kevlar, alongside multi-layered constructions and features such as Multi-directional Impact Protection Systems (MIPS) for enhanced rotational force reduction.3

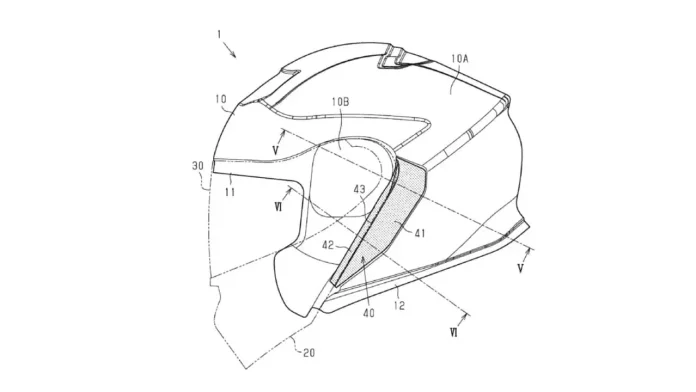

Shoei’s patented curved design seamlessly integrates the shell, visor, and chin bar for unparalleled aerodynamics and enhanced safety.

2.2. Inherent Design Compromises and Rider Pain Points

Despite their significant versatility and growing popularity, modular helmets are not without inherent design compromises. The very mechanism that enables the chin guard to flip up often necessitates bulky hinges, visible seams, and awkward angles where the moving parts connect to the main shell. These design elements are not merely aesthetic imperfections; they can disrupt the helmet’s airflow, potentially increasing aerodynamic drag and turbulence, and, more critically, may introduce perceived or actual weak points in the event of a crash .

Rider feedback frequently highlights increased wind noise as a common complaint when compared to traditional full-face helmets, a trade-off many riders accept for the added convenience of modularity.5 Modular helmets are also typically heavier than their full-face counterparts due to the additional mechanical components required for the flip-up mechanism.5 While some riders report adapting to this extra weight over time, it can contribute to rider fatigue on extended journeys.5

Concerns about the structural integrity of the movable chin bar persist among some riders, despite advancements. However, modern modular helmets with P/J homologation are rigorously certified for safe use in both open and closed configurations, directly addressing these safety perceptions.5 It is worth noting that historically, some older modular designs were only certified for use as open-face helmets.5 Further rider pain points include chin vent levers that can be small and challenging to operate with gloved hands, a limited number of detents for precise visor positioning, and internal sun visors that may not extend low enough to fully cover the rider’s field of vision.10

The inherent tension between the versatility of a modular helmet and the pursuit of optimal performance and safety is a fundamental challenge in its design. The “Swiss Army knife” analogy used to describe modular helmets aptly captures this core design dilemma; their strength in offering multiple functionalities also inherently introduces compromises. Shoei’s latest patent represents a targeted effort to minimize these compromises while preserving the core versatility that riders value.

The market for premium helmets is mature, with basic safety and comfort largely established as standard features. In this environment, subtle refinements become crucial differentiators. Shoei’s patent addresses what has been described as “a subtle flaw that most riders probably never noticed—yet it’s hard to unsee once it’s pointed out” . This approach indicates a strategy of refinement aimed at discerning consumers who value incremental improvements in aesthetics, aerodynamics, and perceived safety, even when the existing product is already considered safe and comfortable. This focus on perfecting minute details can create a new, higher standard that, once experienced, becomes a new expectation for premium modular helmets.

The following table summarizes the common challenges associated with modular helmets and how Shoei’s new patent aims to address them:

Table 2: Modular Helmet Challenges and Shoei’s Proposed Solutions

| Modular Helmet Challenge | Rider Pain Point/Consequence | Shoei’s Patent Solution | Claimed Benefit |

| Bulky Hinges/Visible Seams | Aesthetically unappealing, potential wind ingress | Additional curved piece/transition piece, Recessed “second attachment surface” | Cleaner look, minimized visible transition |

| Aerodynamic Drag/Turbulence | Reduced airflow, increased wind noise, rider fatigue | Smoother transition between shell and moving parts | More aerodynamic, improved airflow, reduced turbulence |

| Perceived Weak Points/Impact Dispersion | Potential safety concern at chin bar joint | Seamless integration, even distribution of materials | Disperses impact forces more effectively, reduced potential weak points |

| Wind Noise | Discomfort, reduced communication clarity | Smoother external surface, improved sealing | Quieter ride, reduced wind noise |

| Manufacturing Consistency | Inconsistent material distribution, unpredictable safety | Consistent shell thickness, easier molding | Even material distribution, reliable structural integrity |

3. Shoei’s Seamless Design Patent: A Technical Analysis

3.1. Detailed Explanation of the “Curved Piece” and “Second Attachment Surface”

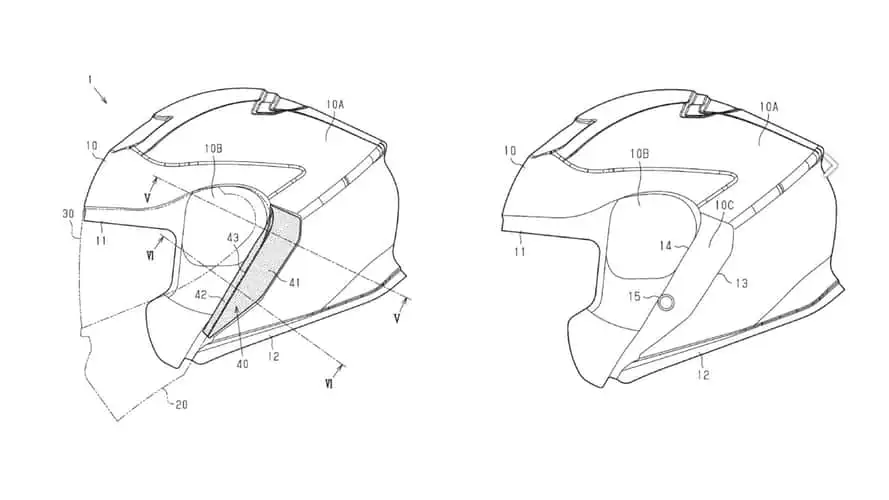

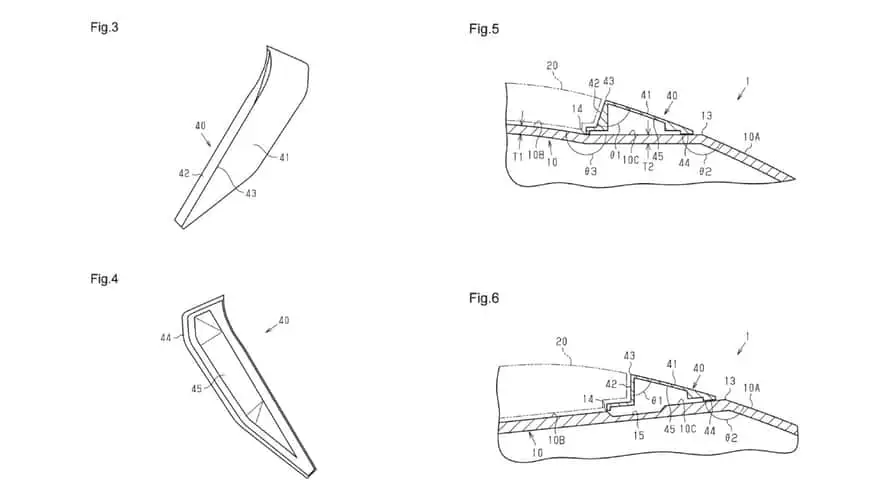

Shoei’s recently filed patent introduces an innovative design centered on an “additional curved piece” specifically engineered to smooth the transition between the main helmet shell and the movable visor and chin bar.14 This approach directly confronts the long-standing issues prevalent in traditional modular helmet designs, namely bulky hinges, visible seams, and awkward angles, which can compromise both the helmet’s aesthetics and its functional performance.14

The core of this innovation lies in the insertion of an “extra component: a kind of transition piece that bridges the gap and blends everything together more seamlessly”.14 This element effectively eliminates the abrupt step that typically exists where the moving parts directly attach to the helmet shell. The helmet’s outer shell maintains its conventional round contour, but it now incorporates a “recessed section that gently slopes outward.” This specifically designed sloped area is formally referred to as the “second attachment surface” within the patent documentation.14

The new exterior component, which is essentially a curved panel featuring its own subtle ridge-line, is precisely fitted onto this “second attachment surface.” This panel then serves to cover the joint between the main shell and the flip-up elements, such as the chin guard and face shield. The result is a significantly smoother and more integrated shape that minimizes visible transitions, creating a unified appearance.14

While the exact patent number for this “recently filed” design is not explicitly detailed in the provided information, the comprehensive description aligns with the user query’s focus. This design is distinct from older Shoei patents, such as EP-0479407-A2 from 1992 or EP-1396200-A4 from 2004.15 The mention of “patent pending” for aerodynamic features in other Shoei models, like the X-Fifteen full-face helmet 18, further indicates Shoei’s ongoing commitment to design innovation and the protection of its intellectual property.

Discover the ingenious curved panel that flawlessly integrates the chin bar, transforming the helmet’s profile for a sleek, unified look

3.2. Claimed Aerodynamic, Safety, and Manufacturing Benefits

Shoei’s new modular helmet design patent outlines several key benefits across critical performance areas.

Aerodynamic Benefits: The primary aerodynamic claim is that the seamless design results in a helmet that “looks cleaner and more aerodynamic”.14 By eliminating sharp angles and exposed mounting points, the smooth transition created by the curved piece is expected to reduce wind resistance and turbulence. This enhancement aims to improve rider comfort and stability, particularly at higher speeds.14 This aligns with fundamental aerodynamic principles, where smoother surfaces are known to reduce drag by promoting laminar boundary layers, thereby minimizing pressure drag caused by detached wakes.19 The aesthetic improvement of a cleaner look is thus a direct consequence of optimizing airflow and reducing aerodynamic inefficiencies.

Safety Benefits: The patent asserts that this new design “may also disperse impact forces more effectively in the event of a crash”.14 The smoothing of rough edges and the creation of a more seamless interface between the movable chin bar and the main shell are intended to distribute impact forces more evenly across the helmet’s structure.14 Helmets fundamentally protect by allowing their outer shell to deform and their inner liner (typically Expanded Polystyrene or EPS) to compress, thereby spreading impact forces and absorbing energy to reduce the force transmitted to the head.21 For this protective mechanism to be consistent and effective, uniform material distribution throughout the shell is critical.14 The design aims to enhance this consistency, leading to more predictable and reliable protective performance. This represents an attempt to transform a traditionally perceived area of vulnerability—the modular joint—into an engineered point of strength, capable of more effectively distributing impact loads.

Manufacturing Benefits: The patent also highlights practical advantages for production, specifically “more consistent shell thickness,” which simplifies the molding process.14 This uniformity in thickness, in turn, facilitates the “evenly distribut[ing] materials like fiberglass or composite fiber layers” during manufacturing.14 Shoei’s existing Advanced Integrated Matrix (AIM) and AIM+ shell molding technologies already involve hand-laid multi-ply matrices of fibers and resin to achieve strength and elasticity.25 The new design could further optimize this process by reducing the inherent complexity of molding the chin bar junction, leading to more consistent quality control and a more reliable end product. This manufacturing innovation serves as a direct enabler of enhanced safety, as consistent material distribution is paramount for predictable impact absorption.

3.3. Initial Observations into How This Addresses Traditional Modular Helmet Flaws

The patent directly targets the aesthetic and functional shortcomings that have long been points of criticism for modular helmets, specifically the “bulky hinges, visible seams, and awkward angles” . By creating a smoother, more integrated external surface, the design aims to mitigate two pervasive issues: wind noise and aerodynamic turbulence, both of which are common complaints among modular helmet users.5 This demonstrates a synergistic relationship where improvements in airflow naturally lead to benefits in acoustics, reinforcing the overall rider experience.

The claimed improvement in impact force dispersion suggests a direct enhancement to the structural integrity of the chin bar joint, an area often perceived as a potential weak point in modular designs.5 This moves the innovation beyond mere aesthetics to a fundamental safety improvement. The approach of addressing a “subtle flaw that most riders probably never noticed—yet it’s hard to unsee once it’s pointed out” reflects a sophisticated market strategy. Rather than addressing obvious deficiencies, Shoei aims to elevate the user experience by perfecting details. This creates a new, higher standard that, once experienced, becomes a new expectation for premium modular helmets, potentially setting a new benchmark for “premium” in the modular segment.

The following table summarizes the specific design features of Shoei’s patent and their claimed benefits:

Table 1: Shoei Patent Design Features and Claimed Benefits

| Patent Design Feature | Aerodynamic Benefit | Safety Benefit | Manufacturing Benefit |

| Additional curved piece/transition piece | Cleaner look, more aerodynamic, reduced drag/turbulence | More effective impact force dispersion | Easier molding, more consistent shell thickness |

| Recessed “second attachment surface” | Smoother airflow over junction | Reduced potential weak points at joint | Facilitates even material distribution |

| Smoothing of chin guard/face shield connection | Minimizes visible transition, improved aesthetics | Distributes impact forces more evenly | Streamlined production process |

4. Addressing Core Modular Helmet Challenges

4.1. Analysis of How the Patent Aims to Mitigate Noise, Bulkiness, and Perceived Weak Points

Shoei’s seamless design, by creating a smoother transition between the helmet shell and its moving parts, is directly intended to reduce wind noise and turbulence. This addresses a pervasive and significant complaint among modular helmet users, who often report higher noise levels compared to full-face helmets.5 Shoei’s Neotec 3, which likely incorporates principles from this patent, explicitly highlights “maximum silencing” and improved noise reduction through features like a thicker neck roll, chin curtain, and tighter face seal.27 The company’s long-standing practice of extensive wind tunnel testing is aimed at achieving an “optimal balance between airflow and silence”.25 This demonstrates a clear understanding that improved airflow management around the helmet directly contributes to a quieter riding experience, reinforcing the overall rider comfort.

The patent’s emphasis on “seamless” integration and minimizing “bulky hinges, visible seams, and awkward angles” directly tackles the aesthetic and practical bulkiness often associated with modular helmets . While modular helmets are inherently heavier due to their complex mechanisms 5, design refinements like those proposed aim to create a more compact and streamlined profile, making the helmet feel less cumbersome. The Neotec 3’s description as “sleeker, quieter and more aerodynamic” with a “sculptural, fluid helmet shape” 29 aligns with this objective, indicating that design improvements can mitigate the perception of bulkiness even if the absolute weight remains higher than full-face counterparts.

Furthermore, the patent explicitly claims that the seamless design “may also disperse impact forces more effectively in the event of a crash”.14 This directly challenges the common perception that modular helmets, due to their movable chin bar, inherently possess weak points at the joint.5 The use of a “second attachment surface” and a “curved panel” to bridge the gap suggests a more robust, load-distributing structure at this critical junction.14 Modern helmet safety standards, such as DOT, ECE 22.06, and Snell, include rigorous tests for chin bar integrity and impact absorption, which this design aims to enhance.13 The Neotec 3’s all-metal, 360-degree pivoting lock system for the face cover further reinforces security against accidental opening during a fall.28 This represents a deliberate engineering effort to reinforce the modular mechanism, transforming a perceived vulnerability into an area of engineered strength.

The Neotec 3’s specific two-step chin bar mechanism, which includes a “city mode” detent, illustrates that modular helmet innovation is increasingly driven by specific use-case scenarios beyond just high-speed highway riding.27 This refinement acknowledges that commuters and touring riders frequently encounter stop-and-go traffic or need to interact at low speeds, demonstrating a growing sophistication in tailoring modular functionality to diverse rider needs for practical, everyday convenience.

4.2. Discussion of Impact Force Dispersion and Structural Integrity Improvements

Motorcycle helmets are fundamentally engineered to attenuate head accelerations during an impact. This is achieved through a multi-stage process where the hard outer shell deforms and potentially cracks, while the inner Expanded Polystyrene (EPS) liner compresses. This combined action serves to distribute impact forces over a wider surface area and absorb kinetic energy, thereby reducing the force transmitted to the rider’s head and brain.21

A critical factor for consistent and effective impact absorption across the entire helmet surface is uniform shell thickness and consistent material distribution.14 Shoei’s patent directly aims to improve this consistency, which translates to more predictable and reliable protective performance. If material distribution is uneven, certain areas might be weaker or stronger than intended, leading to unpredictable failure modes in a crash. By simplifying the interface between the fixed shell and movable chin bar, Shoei can achieve better control over the shell’s overall thickness and material layup, ensuring that the theoretical safety benefits of its chosen materials and shell design are consistently realized in mass production.

Research indicates that impacts with non-planar surfaces or those occurring at awkward angles can lead to more concentrated helmet damage and an increased risk of head injury.24 By smoothing these transitions, Shoei’s seamless design could mitigate these risks, allowing the helmet to glide or deform more uniformly upon impact, potentially reducing localized stress concentrations.

The chin bar area is statistically a high-impact zone in motorcycle accidents, with studies indicating that approximately 50% of severe impacts occur at the front of the helmet.35 Finite element modeling has demonstrated that stiffening the helmet shell and optimizing the chin bar foam can significantly reduce peak head acceleration during impact.35 Shoei’s approach of a more integrated, seamless chin bar aims to improve its structural contribution to overall impact protection, making it less of a separate, vulnerable component and more of an extension of the main protective shell. This engineering effort seeks to transform a perceived weakness into a robust, load-bearing area, enhancing the helmet’s overall ability to distribute impact forces effectively.

5. Competitive Landscape and Innovation Benchmarking

5.1. Overview of Key Modular Helmet Competitors and Their Innovations

The modular helmet market is highly competitive, with several manufacturers pushing the boundaries of design, safety, and rider comfort.

- Schuberth: This German manufacturer is widely recognized for its exceptional aeroacoustics, with models like the C5 achieving a remarkable 85 dB(A) at 62 mph (100 km/h) on a naked bike, making them among the quietest modular helmets available.6 Schuberth helmets utilize Direct Fiber Processing (DFP) fiberglass shells combined with carbon fiber for superior shock absorption and lighter weight.31 Their innovations include a Visor Memory Function, integrated speakers, P/J certification (allowing safe riding with the chin bar up), and an Anti Roll-Off System (AROS) for enhanced security.30 The C5 also features a specific locking mechanism to securely hold the chin bar in the up position.30

- AGV: The AGV Tourmodular helmet exemplifies a focus on premium qualities, featuring dual P/J Homologation and a 2-stage chin guard mechanism. Its shell is specifically designed for maximum aerodynamic performance, with a notable claim of “0 dynamic weight at 80 mph (130 km/h)”.12 Construction involves an ultra-strong carbon-aramid-fiberglass blend with five-density EPS liners for optimal impact management.12 AGV also integrates a chin curtain designed to significantly reduce wind noise and turbulence, contributing to a quieter ride.38

- Nolan: Nolan’s N120-1 showcases an innovative “flip-back” chin guard that can rotate 180 degrees to rest at the rear of the helmet, enhancing aerodynamics in jet mode.39 It features a “Dual Action” chin guard opening system with double levers for smooth operation and carries P/J homologation.39 Nolan helmets are often praised for their convenience and comfort, with a good track record in chin bar safety testing, where the mechanism reportedly does not fail on impact.6 However, some models may be comparatively heavier or louder than their premium counterparts.6

- HJC: HJC distinguishes itself by operating its own state-of-the-art wind tunnel laboratory, enabling comprehensive testing of aerodynamics, ventilation, and noise.41 The RPHA 91 model incorporates a PIM EVO Shell, a new material blend including carbon-aramid, carbon fiber, glass fiber, organic non-woven fabric, and natural linen fiber, for enhanced shock resistance and a lightweight profile.43 Its chin bar features a dual-axis pivot mechanism designed to minimize air resistance and wind noise by bringing the chin bar closer to the shell in the closed position, and the chin curtain retracts when opened for ease of use.43 HJC also offers seamlessly integrated SMART HJC communication systems.44

- Sena: A leader in “purpose-built smart helmets,” Sena’s Phantom helmet integrates communication systems (Mesh Intercom, Harman Kardon sound, AI-based Noise Cancellation) directly into the helmet’s core structure from the ground up.45 This eliminates bulky external components, preserving the helmet’s sleek design and structural integrity, thereby enhancing both safety and audio experience.45 This deep integration of electronic features into the helmet’s core design represents a significant step in the evolution of rider technology.

- LS2: The LS2 Advant X features a high-performance fiberglass composite shell and a Kinetic Polymer Alloy chin bar, with DOT/ECE certification and robust metal chin bar locking components.46 User reviews suggest that even budget-friendly LS2 modular helmets can offer decent real-world safety, with one user reporting good performance in a highway accident.8

- Scorpion EXO: The Scorpion EXO-GT930 Transformer offers significant versatility, allowing riders to convert the helmet from full-face to open-face mode in seconds without tools. It also includes an integrated SpeedView drop-down sun visor for convenience.14

5.2. Comparison of Approaches to Chin Bar Integration, Aerodynamics, and Noise Reduction

Manufacturers employ diverse strategies to address the challenges inherent in modular helmet design, particularly concerning chin bar integration, aerodynamics, and noise reduction.

Chin Bar Integration: While competitors like Schuberth and Nolan focus on the mechanism of the chin bar (e.g., locking in the up position, 180-degree flip-back), and HJC on its pivot geometry for proximity to the shell, Shoei’s patent specifically addresses the interface between the chin bar and the main shell. Its “seamless” design aims to eliminate visible steps and create a continuous, blended surface, fundamentally altering the aesthetic and structural connection at the joint itself, rather than just the pivot point.14 This represents a nuanced differentiation, moving beyond just how the chin bar moves to how it

looks and performs as an integrated part of the shell.

Aerodynamics: Most premium manufacturers, including Shoei, Schuberth, and HJC, heavily rely on advanced wind tunnel testing to optimize shell designs for reduced drag and turbulence.25 AGV’s claim of “0 dynamic weight at 80 mph” for its Tourmodular highlights a focus on mitigating perceived weight through aerodynamic efficiency.12 Shoei’s patent, by smoothing the chin bar junction, directly targets a common area of aerodynamic disruption in modular helmets, aiming to minimize wind resistance and improve airflow across this critical area.14 The seamless design contributes to a more efficient aerodynamic profile, which not only enhances stability but also contributes to overall rider comfort.

Noise Reduction: This remains a major battleground for modular helmet manufacturers. Schuberth consistently receives high praise for its low noise levels, achieved through optimized shell design and neck roll concepts.6 Shoei’s Neotec 3 also emphasizes noise reduction through a tighter neck roll, chin curtain, and improved face seal.27 HJC utilizes its wind tunnel for noise testing 41, and Sena’s integrated smart helmets feature advanced AI-based noise cancellation and acoustically optimized internal chambers.45 Shoei’s patent, by creating a seamless external surface, directly contributes to reducing wind ingress and turbulence-induced noise, which are primary sources of discomfort for riders.14 The interplay between aerodynamics and acoustics is evident here, as improvements in airflow management inherently lead to a quieter ride.

5.3. Assessment of How Shoei’s Patent Differentiates Its Offering

Shoei’s patent represents a strategic refinement rather than a radical functional overhaul of modular helmets . It targets a “subtle flaw” that, while perhaps unnoticed by many, becomes glaring once pointed out, reflecting Shoei’s meticulous attention to detail. This approach of identifying and resolving a “subtle flaw” can create a new market opportunity, potentially setting a new standard for perceived quality and user experience.

Unlike competitors who primarily focus on the mechanics of the chin bar or overall shell aerodynamics, Shoei’s patent specifically addresses the interface between the chin bar and the main shell. This focus on a truly seamless visual and structural transition is a nuanced differentiation. While other brands like Schuberth and AGV claim “seamless linings” or “compact and light design,” Shoei’s patent details a mechanical solution for the external seamlessness of the chin bar junction itself. This suggests Shoei is attempting to define a new standard for perceived quality and aerodynamic efficiency in modular helmets, potentially forcing competitors to invest in similar aesthetic and structural refinements. This could initiate a “seamless” arms race within the premium helmet market.

This approach is highly consistent with Shoei’s brand identity, known for “chasing smaller improvements that add up” and its reputation for high-end, refined products like the Neotec II and RF series. It positions Shoei as a leader in perfecting the user experience, enhancing aesthetics, and bolstering structural integrity at a traditionally compromised junction. The trend across premium brands (Shoei, Schuberth, Sena, HJC) is clearly towards deeper integration of features – not just communication systems, but also aerodynamic elements and structural components. Shoei’s patent exemplifies this by making the chin bar junction an integral, rather than an additive, part of the shell’s fluid design. This suggests that for premium helmets, the future isn’t just about adding features, but about making those features (and even structural elements) an invisible, cohesive part of the overall design, enhancing both performance and user experience.

While modular helmets are generally heavier due to their complex mechanisms, the competitive landscape shows manufacturers are actively working to mitigate this through advanced materials such as carbon fiber and aramid fibers.3 The AGV Tourmodular’s claim of “0 dynamic weight at 80 mph” suggests aerodynamic compensation for static weight.12 This indicates a constant battle between adding desirable features (modularity, integrated communications, sun visors) and managing the resulting weight, which directly impacts rider comfort and fatigue. Shoei’s patent, by aiming for consistent thickness, might contribute to weight optimization, but the fundamental trade-off between weight and enhanced features/safety remains a continuous design challenge across the industry.

The following table provides a comparative analysis of leading modular helmet innovations, highlighting their distinct approaches:

Table 3: Comparative Analysis of Leading Modular Helmet Innovations

| Manufacturer/Model | Chin Bar Mechanism/Hinge Design | Aerodynamic Claims/Features | Noise Reduction Features/Claims | Key Materials | Weight (approx. Size M) | Seamlessness/Integration Claims |

| Shoei Neotec 3 | Seamless transition piece, 360° Pivot locking system, eccentric rotation axis 28 | Wind tunnel tested, sleek shape, shell-integrated spoiler, Aero Deflector, Vortex Generator lip 27 | Maximum silencing, thicker neck roll, chin curtain, tighter face seal 27 | AIM (Advanced Integrated Matrix) Multi-Ply Matrix 47 | 4.15 lbs 49 | “Seamless design,” “sense of unity,” “seamlessly integrated communication system” 28 |

| Schuberth C5 | Locking mechanism for up position, new chin lock mechanism in glass fiber reinforced plastic 30 | Optimized shell design, wind tunnel tested 30 | 85 dB(A) at 62 mph (100 km/h), new neckroll concept 30 | DFP (Direct Fiber Processing) fiberglass with carbon fiber/basalt layer 30 | “Lighter yet safer” than predecessors 30 | “Seamless linings concept,” “perfect integration” (for comms) 30 |

| AGV Tourmodular | 2-stage chin guard mechanism, metal chin guard block system 12 | Shell shape for maximum aerodynamic performance, “0 dynamic weight at 80 mph” 12 | Chin curtain for reduced wind noise and turbulence 38 | Carbon-aramid-fiberglass layered blend, 5-density EPS 12 | Not specified, but “lightweight” 12 | “Seamless integration” (for chin curtain) 38 |

| Nolan N120-1 | “Dual Action” double levers, 180° flip-back chin guard with single pivot mechanism 39 | Enhanced aerodynamics in jet mode (flip-back) 39 | Chin curtain, “AirBooster Technology” ventilation 39 | Lexan Polycarbonate outer shell 40 | 1703 grams (approx. 3.75 lbs) 40 | “Balance of colour and elegant design maintained in all usage configurations” 39 |

| HJC RPHA 91 | Dual-axis pivot mechanism for shell proximity, chin curtain retracts when open 43 | Wind tunnel tested, “streamlined, compact profile” 43 | 3D-engineered low-noise interior, chin bar proximity, SMART HJC integrated comms 43 | PIM EVO Shell (carbon-aramid, carbon fiber, glass fiber, organic non-woven, natural linen) 43 | Not specified, but “lightweight profile” 43 | “Fully integrated into the helmet,” “optimal weight balance and aerodynamic performance” 44 |

| Sena Phantom | Full-face smart helmet, not modular | Sleek, streamlined design, eliminates bulky external components 45 | AI-based Noise Cancellation, optimized internal acoustic chambers 45 | Not specified, but “craftsmanship of a full-face helmet” 45 | Not specified | “Purpose-built smart helmet,” “seamless design,” “factory-built design” 45 |

6. Manufacturing Advancements and Material Science

6.1. Exploration of Shoei’s AIM/AIM+ Molding Process

Shoei’s renowned Advanced Integrated Matrix (AIM) and AIM+ shell molding technology serves as the fundamental bedrock of its helmet construction. This proprietary process involves the meticulous hand-laying of a multi-ply matrix, intricately weaving together layers of fiberglass, organic fibers, and resin.25 This intricate layering technique is specifically designed to achieve an optimal balance of strength and elasticity, resulting in a helmet shell that is both exceptionally robust and remarkably lightweight.25

As a testament to Shoei’s unwavering commitment to quality and accountability, each helmet shell is personally marked by the technician responsible for its creation, endorsing the craftsmanship and ensuring traceability.25 Following the precise molding process, robotically controlled lasers are employed to accurately cut off any protrusions and create the necessary openings for eye ports and ventilation systems. This automation ensures high precision and consistency across all units.25 Before advancing to the painting and final assembly stages, every helmet undergoes a rigorous inspection to verify proper material thickness and weight, thereby maintaining Shoei’s stringent quality standards throughout production.25

Overall, Shoei’s production philosophy emphasizes a meticulous integration of cutting-edge technology, continuous consumer feedback, modern testing practices, and advanced materials. This comprehensive approach is underpinned by nearly 60 years of helmet-building expertise, creating a blend of traditional craftsmanship and high-tech manufacturing.25 The continued emphasis on “hand-laid interwoven layers” and individual technician marking, alongside the use of robotic lasers and wind tunnel testing, highlights a unique blend of traditional craftsmanship and cutting-edge technology. This suggests that for premium helmet manufacturers, human expertise in material layup is still considered superior for achieving the desired properties in complex composite structures, even as automation handles precision finishing tasks.

6.2. How the New Design Simplifies Molding and Ensures Consistent Material Distribution

The recently filed patent explicitly highlights significant manufacturing benefits, including the achievement of “more consistent shell thickness,” which inherently simplifies the complex molding process of modular helmets.14 This improved consistency in shell thickness, in turn, facilitates the “evenly distribut[ing] materials like fiberglass or composite fiber layers” throughout the helmet’s construction.14

Manufacturing complex helmet shells, especially modular ones with intricate geometries, undercuts, and varying wall thicknesses, presents significant challenges in maintaining dimensional accuracy and uniform material flow.50 Precise control over cooling rates and ejection processes is also critical to avoid defects such as warping or incomplete fills.51 By introducing a “transition piece” that bridges gaps and creates a seamless blend between the main shell and the chin bar/face shield, as described in the patent, Shoei’s design could simplify the molding of what would otherwise be a highly complex, single-piece structure. This modular approach to shell construction, where a more uniform main shell integrates with a specialized transition piece, can lead to fewer manufacturing defects and more predictable, consistent material properties across the entire helmet.

Traditional helmet manufacturing techniques, such as “Pressure Bladder” molding, sometimes require designing shells to be larger than ideal to accommodate liners, or can result in rough interfaces at ventilation ports.52 Shoei’s patent aims to smooth these interfaces, not just for aesthetics and aerodynamics, but also for manufacturing precision and structural integrity. This manufacturing innovation serves as a direct enabler of enhanced safety. More consistent shell thickness and material distribution directly translate to more predictable and reliable impact absorption across the helmet’s surface, reducing variability in protective performance in real-world scenarios.

6.3. Broader Trends in Helmet Materials and Manufacturing

The helmet industry continues to evolve rapidly, driven by advancements in material science and manufacturing processes.

Advanced Materials: The industry has transitioned significantly from early leather and basic plastics to high-performance composites such as polycarbonate, carbon fiber, Kevlar, and fiberglass. These materials are chosen for their superior impact absorption and energy distribution properties.3 Carbon fiber, in particular, is highly valued for its exceptional strength-to-weight ratio, leading to lighter yet stronger helmets.2

Multi-layered Construction: Modern helmets commonly feature multi-layered constructions, combining a hard outer shell with energy-absorbing foam interiors. Materials like Expanded Polystyrene (EPS), Expanded Polypropylene (EPP), or advanced structures like Koroyd are used to dissipate impact energy more effectively while maintaining a lightweight profile.3 Multi-density EPS liners are a standard feature in premium helmets, offering varied absorption capabilities for different impact severities.3

Sustainable Materials: There is a growing industry emphasis on eco-friendly solutions, with ongoing research and development exploring biodegradable polymers, recycled plastics, and plant-based resins as more sustainable alternatives for helmet production.54

Customization and Adaptive Fit: Advancements in 3D scanning and printing technologies, alongside materials like memory foam and adjustable strap systems, are enabling highly personalized and adaptive helmet fits. This ensures optimal comfort and protection tailored to individual head shapes.54 Shoei itself offers an industry-leading number of shell sizes and various liner and cheek pad thicknesses to achieve customizable fits, demonstrating a commitment to personalized comfort.25

Manufacturing Precision: The adoption of Computer-Aided Design (CAD) software for design and Computer Numerical Control (CNC) machines for manufacturing has significantly enhanced the accuracy and precision in helmet mold design and production.50 Robotic cutting, as employed by Shoei, further refines the finishing process, ensuring consistency and quality.25

Modular Component Design for Sustainability: Some manufacturers are exploring modular helmet designs that allow for the replacement of specific components rather than the entire helmet. This trend not only reduces environmental impact but also offers cost-effectiveness to consumers by extending product lifespan and reducing waste.54

7. Conclusion

Shoei’s recently filed patent for a seamless modular helmet design represents a significant step in the continuous evolution of motorcycle head protection. By introducing an “additional curved piece” and a “second attachment surface,” the design directly addresses long-standing compromises in modular helmet architecture, particularly the bulky hinges, visible seams, and awkward angles that have historically impacted aesthetics, aerodynamics, and perceived safety.

The claimed benefits of this innovation are multi-faceted. Aerodynamically, the smoother transition aims to reduce drag and turbulence, contributing to a cleaner look and potentially a quieter ride—a common desire among modular helmet users. From a safety perspective, the design is posited to disperse impact forces more effectively by promoting consistent shell thickness and material distribution, thereby enhancing structural integrity at a critical junction. Manufacturing benefits, such as simplified molding and more uniform material lay-up, underscore the practical advantages that translate directly into consistent product quality and reliable protective performance.

This strategic refinement aligns perfectly with Shoei’s brand identity, known for meticulous attention to detail and a commitment to incremental improvements that collectively elevate the user experience. By targeting a “subtle flaw” that, once identified, becomes difficult to ignore, Shoei is poised to set a new benchmark for premium modular helmets, potentially influencing future design trends across the industry.

The patent reflects a broader trend towards deeper integration of features and structural components, moving beyond mere functionality to a cohesive, high-performance product where form and function are seamlessly intertwined. While modular helmets inherently face challenges such as increased weight compared to full-face counterparts, ongoing advancements in materials science and manufacturing precision continue to mitigate these trade-offs, demonstrating a persistent drive towards safer, more comfortable, and aesthetically refined rider protection.

Sources

- HISTORY OF MOTORCYCLE HELMETS – STUDDS, accessed on June 28, 2025, https://www.studds.com/blog/history-of-motorcycle-helmets

- 100 years History of Motorcycle helmet evolution – Champion Helmets, accessed on June 28, 2025, https://www.championhelmets.com/us/magazine/post/100-years-History-of-Motorcycle-helmet-evolution

- The Evolution of Motorcycle Helmet Technology, accessed on June 28, 2025, https://www.lazerhelmets.net/evolution-of-motorcycle-helmet-technology/

- A Quick Look at the Evolution of Motorcycle Helmet Safety Technology – webBikeWorld, accessed on June 28, 2025, https://www.webbikeworld.com/a-quick-look-at-the-evolution-of-biker-safety-gear/

- Are modular helmets safe? : r/motorcycles – Reddit, accessed on June 28, 2025, https://www.reddit.com/r/motorcycles/comments/1aupvcp/are_modular_helmets_safe/

- Modular Helmet Honest review : r/motorcycle – Reddit, accessed on June 28, 2025, https://www.reddit.com/r/motorcycle/comments/1bm8a7g/modular_helmet_honest_review/

- What are your opinions on modular helmets? : r/motorcycles – Reddit, accessed on June 28, 2025, https://www.reddit.com/r/motorcycles/comments/3se0nt/what_are_your_opinions_on_modular_helmets/

- Are modular helmets worth it ? : r/motorcyclegear – Reddit, accessed on June 28, 2025, https://www.reddit.com/r/motorcyclegear/comments/1l3ox84/are_modular_helmets_worth_it/

- Modular helmets: Pros and cons? : r/motorcycles – Reddit, accessed on June 28, 2025, https://www.reddit.com/r/motorcycles/comments/13ynia2/modular_helmets_pros_and_cons/

- Shoei GT Air 2 vs Neotec 2: My Honest Take After Long Rides – BikerGuides, accessed on June 28, 2025, https://bikerguides.com/shoei-gt-air-2-vs-neotec-2/

- Review: Shoei Neotec II Helmet – RoadRUNNER Motorcycle Touring & Travel Magazine, accessed on June 28, 2025, https://www.roadrunner.travel/products/review-shoei-neotec-ii-helmet/

- AGV Tourmodular Helmet – Cycle Gear, accessed on June 28, 2025, https://www.cyclegear.com/gear/agv-tourmodular-helmet

- The Ultimate Guide to Understanding DOT, SNELL, and ECE Motorcycle Helmet Ratings, accessed on June 28, 2025, https://sprocketz.store/blogs/news/the-ultimate-guide-to-understanding-dot-snell-and-ece-motorcycle-helmet-ratings

- Shoei Found a Problem With Modular Helmets, So It Fixed It – RideApart.com, accessed on June 28, 2025, https://www.rideapart.com/news/764032/shoei-new-modular-helmet-design-patent/

- EP-0479407-A2 – Helmet – Unified Patents Portal, accessed on June 28, 2025, https://portal.unifiedpatents.com/patents/patent/EP-0479407-A2

- Motorcycle helmet – USD526092S1 – Google Patents, accessed on June 28, 2025, https://patents.google.com/patent/USD526092S1/en

- EP-1396200-A4 – Helmet – Unified Patents Portal, accessed on June 28, 2025, https://portal.unifiedpatents.com/patents/patent/EP-1396200-A4

- X-Fifteen | FULL-FACE HELMET|SHOEI WORLDWIDE, accessed on June 28, 2025, https://www.shoei.com/worldwide/en/helmet/fullface/x-fifteen/

- Air Friction – matte surface vs smooth | Page 2 | Disc Golf Course Review, accessed on June 28, 2025, https://www.dgcoursereview.com/threads/air-friction-matte-surface-vs-smooth.106016/page-2

- Why does a turbulent boundary layer cause more friction drag than a laminar boundary layer? – Aviation Stack Exchange, accessed on June 28, 2025, https://aviation.stackexchange.com/questions/55438/why-does-a-turbulent-boundary-layer-cause-more-friction-drag-than-a-laminar-boun

- What You Should Know About Motorcycle Helmets – MSF, accessed on June 28, 2025, https://msf-usa.org/wp-content/uploads/2023/03/how-helmets-work.pdf

- Motorcycle helmet standards | Dr. John Lloyd | brain injury expert, accessed on June 28, 2025, https://drbiomechanics.com/motorcycle-football-helmet-expert/motorcycle-helmet-standards/

- Evaluation of Impact Energy Absorption by Natural Fiber Composites in Motorcycle Helmets, accessed on June 28, 2025, https://www.mdpi.com/2076-3417/15/2/653

- Motorcycle Helmet Impact Behavior Depends on Impact Surface Shape – Research, accessed on June 28, 2025, https://www-nrd.nhtsa.dot.gov/pdf/bio/proceedings/2012_40/40-11.pdf

- shoei-helmets.com, accessed on June 28, 2025, https://shoei-helmets.com/technology/production-quality.html

- SHOEI PRODUCTION & QUALITY ASSURANCE – Whites Powersports, accessed on June 28, 2025, https://www.whitespowersports.com/blogs/news/shoei-production-quality-assurance

- Shoei Neotec 3 Modular Helmet: Review & Neotec 2 Compare – It’s Better On The Road, accessed on June 28, 2025, https://itsbetterontheroad.com/gear/shoei-neotec-3-review/

- NEOTEC 3 | SYSTEM HELMET|SHOEI WORLDWIDE, accessed on June 28, 2025, https://www.shoei.com/worldwide/en/helmet/system/neotec_3/

- Neotec 3 – Shoei® Europe, accessed on June 28, 2025, https://www.shoei-europe.com/products/neotec3/

- C5 – Schuberth, accessed on June 28, 2025, https://schuberth.com/us/c5

- C5 – SCHUBERTH, accessed on June 28, 2025, https://www.schuberth.com/en/c5

- On noise reduction of motorcycle helmets – White Rose Research Online, accessed on June 28, 2025, https://eprints.whiterose.ac.uk/id/eprint/192120/1/on_noise_reduction_of_motorcycle_helmets.pdf

- Shoei Neotec 3 Helmet – Cycle News, accessed on June 28, 2025, https://www.cyclenews.com/2024/05/article/shoei-neotec-3-helmet/

- Snell helmets certification – Testing, accessed on June 28, 2025, https://smf.org/testing

- Response of a full-face motorcycle helmet FE model to the UNECE 22.05 chin bar impact test | Request PDF – ResearchGate, accessed on June 28, 2025, https://www.researchgate.net/publication/304661770_Response_of_a_full-face_motorcycle_helmet_FE_model_to_the_UNECE_2205_chin_bar_impact_test

- Everything You Need to Know – Shoei Neotec 3 Modular Helmet – Motorcyclist, accessed on June 28, 2025, https://www.motorcyclistonline.com/gear/shoei-neotec-3-modular-helmet-everything-you-need-to-know/

- Schuberth Modular Helmets, accessed on June 28, 2025, https://www.championhelmets.com/us/schuberth/modular-helmets.html

- AGV Tourmodular helmet Chin Curtain Black | Motardinn – Tradeinn, accessed on June 28, 2025, https://www.tradeinn.com/motardinn/en/agv-tourmodular-helmet-chin-curtain/138357554/p

- N120-1 Travelling Helmet – NOLAN, accessed on June 28, 2025, https://nolan-helmets.com/en_GB/products/n120-1-n1f-eu

- Nolan N120-1 – Review and Road-Test – Champion Helmets, accessed on June 28, 2025, https://www.championhelmets.com/us/magazine/post/Nolan-N120-1-Review-and-Road-Test

- RESEARCH & DEVELOPMENT – HJC Sports, accessed on June 28, 2025, https://hjcsports.com/pages/research-development

- HJC FURION 3 Road Helmet | Aerodynamic, Lightweight, accessed on June 28, 2025, https://www.anjoycycle.com/products/hjc-furion-30-road-helmet

- RPHA 91 – HJC Helmets, accessed on June 28, 2025, https://hjchelmets.us/pages/rpha-91

- RPHA 91 – HJC HELMETS EUROPE, accessed on June 28, 2025, https://hjchelmets.eu/pages/rpha-91

- PHANTOM – SENA The Best Ever Purpose-Built Motorcycle Smart Helmet, accessed on June 28, 2025, https://www.sena.com/product/phantom/

- Modular Helmets – Speed Addicts, accessed on June 28, 2025, https://www.speedaddicts.com/modular-helmets/

- Neotec II – SHOEI® Helmets North America, accessed on June 28, 2025, https://shoei-helmets.com/models/neotec-ii/

- Shoei Neotec 3 Helmet Redesigned for 2024 – GP Bikes, accessed on June 28, 2025, https://www.gpbikes.com/the-riders-seat/new-shoei-neotec-3-helmet-2024

- Neotec 3 – SHOEI® Helmets North America, accessed on June 28, 2025, https://shoei-helmets.com/models/neotec-3/

- Helmet Mould Guide(2025), accessed on June 28, 2025, https://www.immould.com/helmet-mould/

- Complex Molding and the Challenges of Manufacturing Precision Parts | Thogus, accessed on June 28, 2025, https://www.thogus.com/blog/post/complex-molding-and-the-challenges-of-manufacturing-precision-parts/

- EP2289360A2 – Molded motorcycle helmet and method of manufacture – Google Patents, accessed on June 28, 2025, https://patents.google.com/patent/EP2289360A2/en

- Cycling Helmet Testing & Certification Explained – Koroyd, accessed on June 28, 2025, https://koroyd.com/blog/cycling-helmet-testing

- The Future of Protective Helmets: Innovations Shaping Safety Gear, accessed on June 28, 2025, https://www.marketresearchintellect.com/blog/the-future-of-protective-helmets-innovations-shaping-safety-gear/

- Design and manufacturing processes of half face motorcycle palm fiber reinforced composite polymer – ResearchGate, accessed on June 28, 2025, https://www.researchgate.net/publication/358714721_Design_and_manufacturing_processes_of_half_face_motorcycle_palm_fiber_reinforced_composite_polymer

- History and evolution of cycling helmets – Cassiopeia, accessed on June 28, 2025, https://cassiopeia.cc/blogs/news/history-of-cycling-helmets

Our Social Media Handles

- Instagram : LivingWithGravity

- Medium : Akash Dolas

- YouTube Channel : Gear and Shutter