The new Audi Vehicle Safety Center (AFZ) in Ingolstadt marks a significant investment in safety research, technology, and testing capabilities for Audi, emphasizing their commitment to not just meeting but surpassing international safety standards.

The AFZ has a number of features that make it unique, including

- A 250-meter (820 ft) run-up track

- A mobile 100-ton crash block

- The ability to collide two vehicles at a 90-degree angle

- A wide range of crash test dummies

- High-speed cameras and motion tracking

- A large number of sensors

- 3D scanners

- A back-end system that integrates data from all of the above sources

Here are the main takeaways

1. Infrastructure & Features

- Investment: Around 100 million euros.

- Construction Duration: Three years.

- Size: Core area of 130 by 110 meters with a height of 20 meters.

- Crash Arena: A support-free area measuring 50 by 50 meters.

- Run-up Tracks: Total length of 250 meters, facilitating tests at high speeds.

- Crash Block: A movable and rotatable 100-ton block.

- Miscellaneous: “flying floor” for sideways vehicle crash tests, a dummy lab, component test stands, workshops, and offices.

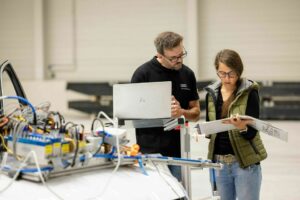

Two crash-test dummies are being prepared for a crash test at the new Vehicle Safety Center

2. Technological and Testing Capabilities

- Several crash lanes for different types of crash scenarios.

- State-of-the-art high-speed cameras and LED lighting.

- Belt systems and airbags are developed with a novel coasting slide with a delay unit

- Use of THOR dummies, with up to 150 sensors for data collection during crash tests.

- Integration of 3D scans, motion tracking, and high-speed cameras.

- Interplay of simulations and physical tests: Tens of thousands of crash simulations monthly, with 60,000+ calculations made for the crash design of a single current model.

The crash arena at the Vehicle Safety Center is a pillar-free space of 50 by 50 meters.

3. Historical Significance

- DKW (part of Audi’s history) initiated systematic rollover tests over 80 years ago, marking the first crash tests in automotive history.

- The first Ingolstadt crash hall was inaugurated in 1970.

- Progressive digitalization focus over the past 25 years.

4. Innovations & Milestones

- The procon-ten safety restraint system was a patented Audi innovation in 1986.

- Machine learning improves airbag control unit software.

- Audi models, including electric ones, consistently achieve top safety ratings in global tests.

Preparations for a crash test at the new Vehicle Safety Center

5. Collaboration and Synergy

- The new AFZ is designed to be adaptive for future developments, signifying long-term foresight.

- Collaboration and exchange with other entities like CARIAD and the Technische Hochschule Ingolstadt, present on the campus, bolster the interdisciplinary approach to safety research and development.

Conclusion

Audi’s commitment to safety, as evidenced by its substantial investment in the Audi Vehicle Safety Center, showcases the brand’s dedication to pushing the boundaries of current safety standards and practices. The inclusion of cutting-edge technology, an interdisciplinary approach, and the combination of historical insights with modern-day innovations underscore Audi’s position as a pioneer in automotive safety.