Ford’s Innovative Modular EV Architecture

Ford’s groundbreaking patent filing introduces a modular EV architecture, revolutionizing electric vehicle manufacturing. This innovative design features a subframe centered around the battery pack, adjustable components for various models, and a bolt-on body structure.

The concept, echoing past industry innovations, allows for customizable wheel and suspension configurations and interchangeable performance packages. While its practical implementation remains uncertain, Ford’s modular approach could significantly impact electric vehicle production, offering unprecedented flexibility and efficiency. This visionary design marks a pivotal advancement in the evolution of electric vehicle technology and the automotive industry’s future.

Introduction: Embracing a New Era in Automotive Design

In the rapidly evolving automotive industry, electric vehicles (EVs) have become a cornerstone of innovation and sustainability. Ford Motor Company, a pioneer in automotive engineering, has recently introduced a groundbreaking modular architecture for EVs, as revealed in a patent filing with the United States Patent and Trademark Office (USPTO). This innovative approach promises to redefine the manufacturing process, offering versatility and efficiency in the production of various electric vehicle models.

The Genesis of Ford’s Modular EV Design

The concept of modular design in the automotive sector is not new. However, Ford’s patent, published on January 2 and initially filed on April 28, 2021, elevates this idea to a new level. This modular EV framework is envisioned as a life-size model kit, incorporating a level of flexibility and adaptability that is unprecedented in electric vehicle manufacturing.

Ford’s Modular EV Architecture: A Detailed Overview

- Subframe Centered on the Battery Pack: The foundation of Ford’s modular EV architecture is a robust subframe designed around the vehicle’s battery pack. This central element is not just a housing for the battery but a versatile base that can be adjusted to accommodate various vehicle models and their unique dimensions.

- Adjustable Crossmembers and Side Rails: Integral to the subframe are adjustable crossmembers and side rails. These components allow for customization in the vehicle’s structure, providing the necessary support and alignment for different types of electric vehicles.

- Front and Rear Subframes with Integrated Components: Additional subframes, equipped with motors, suspension elements, and wheels, can be attached to the primary subframe. This modular approach enables easy assembly and disassembly, allowing for a broad range of vehicle types to be constructed on the same foundational platform.

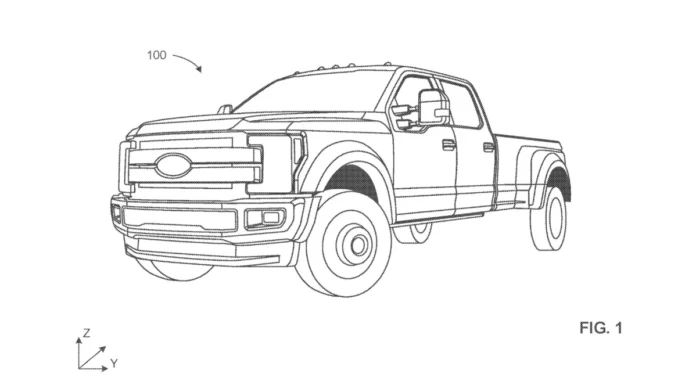

- Bolt-On Body Structure: The final step in Ford’s modular EV design is the addition of the body. In the patent application, an F-Series Super Duty model is used as an example. However, the flexibility of this architecture allows for various vehicle bodies to be bolted onto the rolling chassis, demonstrating the potential for widespread application across different vehicle types.

Historical Context and Industry Comparisons

Ford’s idea of a comprehensive chassis with interchangeable bodies is not an isolated concept in automotive history. It echoes the visions of General Motors’ Autonomy and Hy-Wire concept cars from the early 2000s. EV startup Canoo has also explored this realm with its “skateboard” chassis intended for electric vans and potentially pickups. However, Ford’s proposal incorporates additional features to distinguish its EV models further.

Innovations in Wheel and Suspension Design

One of the notable aspects of Ford’s modular architecture is the versatility in wheel and suspension configurations. The design allows for these assemblies to be inverted, raising ground clearance for pickup trucks and SUVs, or lowering it for sports cars. This adaptability in the chassis design caters to the diverse needs of different vehicle types, from rugged off-road vehicles to sleek, high-performance cars.

Performance Packages and Motor Flexibility

Ford’s modular EV framework also discusses the integration of “performance packages.” These packages feature different motor options, which can be easily swapped thanks to universal mounting hardware. This aspect of the design introduces a level of customization in performance, catering to various consumer preferences and driving conditions.

Feasibility and Future Implementation

While Ford’s modular EV architecture presents a visionary approach to electric vehicle manufacturing, its practical implementation remains uncertain. Automakers often file patents for innovative engineering concepts that do not always translate into production models. The radical nature of this design would necessitate significant changes in assembly plants, supply chains, and potentially in vehicle safety structures.

Conclusion: Pioneering a Modular Future in EV Manufacturing

Ford’s patent filing represents a significant leap in the concept of modular design for electric vehicles. It encapsulates a vision where flexibility, efficiency, and customization are at the forefront of automotive manufacturing. As the industry continues to embrace electric mobility, such innovative approaches will play a crucial role in shaping the future of transportation. The potential impact of Ford’s modular EV architecture on the automotive landscape could be profound, marking a new chapter in the evolution of electric vehicle technology.

Discover the Future of Electric Vehicles with Ford’s Modular EV Architecture: Embrace the Innovation! Stay ahead in the automotive industry by exploring how Ford’s groundbreaking modular design is set to revolutionize electric vehicle manufacturing. Learn more about this innovative approach, its potential impact on flexibility, efficiency, and customization in EV production. Don’t miss out on the latest advancements – join the movement towards a more versatile and sustainable future in automotive technology with Ford’s modular EV architecture. Click to explore and be a part of the revolution in electric vehicle innovation!