Technical Analysis of 2026 World Superbike Development: Bimota KB998 and BMW M 1000 RR Strategic Focus

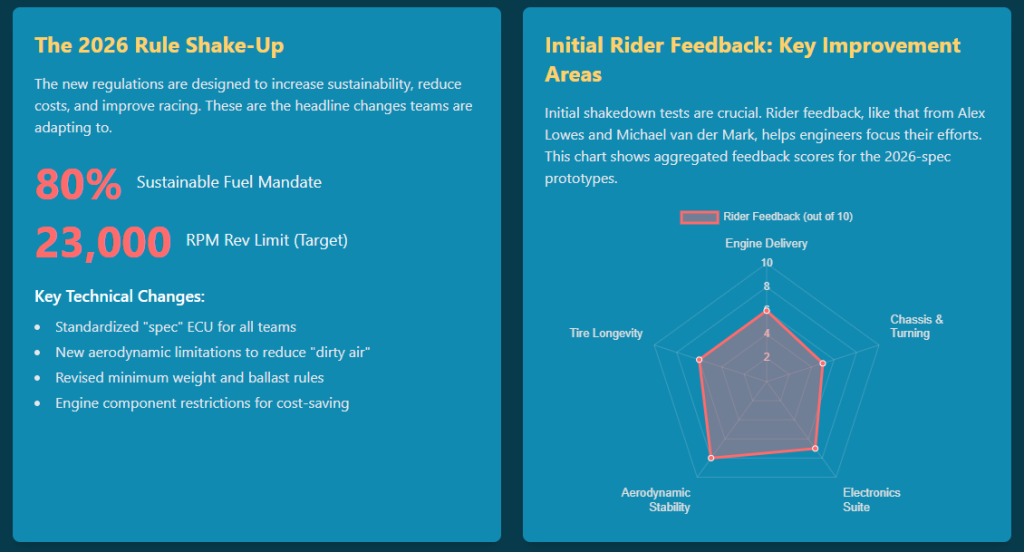

I. Regulatory Context and the Mandate for 2026 Development

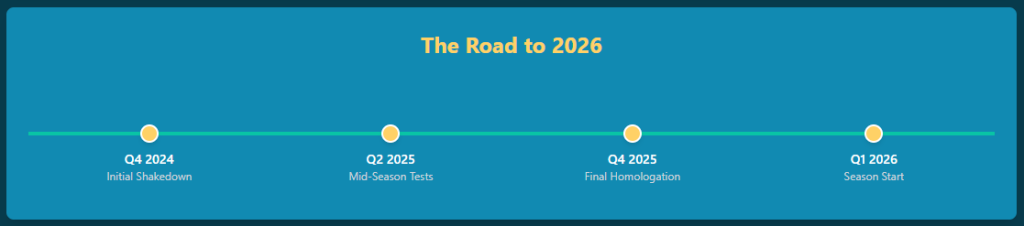

The engineering and strategic development programs for the 2026 MOTUL FIM Superbike World Championship (WorldSBK) are proceeding under a newly refined set of FIM technical and sporting regulations. These constraints critically influence the research and development (R&D) trajectories of manufacturers such as Bimota by Kawasaki Racing Team (KRT) and BMW Motorrad Motorsport. The regulatory environment for 2026 emphasizes cost control, safety, and performance parity through specific limitations on aerodynamic structures and the utilization of performance-enhancing components via the concession system.

I. A. The FIM Homologation and Concession Framework for WorldSBK

The FIM Superbike Commission has introduced specific updates that mandate adjustments to the production and strategic deployment of racing components. These rules are central to understanding the operational constraints faced by high-level development programs.

A significant clarification pertains to the use of Superconcession parts. The regulations stipulate that any Superconcession component earned during the final checkpoint of the previous season (2025) must be officially nominated and fully introduced for the start of the following season (2026) before a manufacturer is eligible to accrue or deploy any additional concession tokens [1]. This regulatory amendment fundamentally alters the strategic timing of development. Teams are prevented from banking tokens indefinitely or reserving new performance parts for deployment during the mid-season European rounds. The mandate forces manufacturers to commit to critical engine or chassis upgrades early, placing immense pressure on the data gathered during post-season and pre-season winter testing to accurately validate component effectiveness. An incorrect early nomination could result in a non-optimal setup remaining locked in for a substantial portion of the championship, jeopardizing competitive standing.

In parallel, there is an increased focus on the structural compliance of aerodynamic devices. The FIM is aligning WorldSBK aero requirements with those previously established in MotoGP, requiring greater structural integrity in wing attachments. Specifically, under normal operating conditions, the attachment of wings and other aerodynamic devices must exhibit a maximum deflection of 10 mm at any point when subjected to a vertical load of 50 N, applied via a 20 mm radius spherical indenter [2]. This requirement demands increased rigidity in the materials and mounting structures for all aero packages. For manufacturers seeking to reduce drag through more aggressive or slender aero designs, this regulation necessitates careful re-engineering to maintain the mandatory compliance without introducing excessive weight or compromising the targeted flow characteristics.

Furthermore, sporting regulations have introduced stricter controls on testing activities, explicitly aiming to reduce overall development costs [2]. For teams relying on extensive track time to validate complex kinematics changes—such as BMW during its rider transition phase—this restriction elevates the necessity of highly efficient data acquisition and correlation during limited official test windows. Additionally, the FIM has increased the required third-party liability insurance for events to 10 million euros, excluding specific territories [2]. For safety compliance, the use of FIM Type 1 or Type 2 airbags will become mandatory from the 2025 season onwards [2].

I. B. The Competitive Benchmark: Ducati’s 2026 Aero and Chassis Evolution

The R&D priorities of rival manufacturers provide critical context for both Bimota and BMW. The aggressive technical development demonstrated by Ducati’s planned 2026 Panigale V4 R iteration sets a high competitive benchmark, particularly in the fields of chassis dynamics and aerodynamics [3].

A major aerodynamic shift is the planned introduction of ‘corner sidepods,’ or downwash ducts, positioned at the bottom of the fairing. This feature, borrowed from MotoGP ground-effect principles, is set to arrive in WorldSBK for the first time. Ducati claims these modifications result in a 25 percent increase in aerodynamic load, translating to an increase in downforce of up to 6kg at a speed of 300 km/h [3]. If successful, this ground-effect stabilization will grant Ducati superior mid-corner stability and enhanced corner-exit acceleration grip. For competing teams, this dictates that any 2026 aerodynamic revision must not only comply with the new FIM deflection limits but also strive for significant downforce and efficiency improvements to negate Ducati’s advantage in high-speed, high-lean scenarios.

On the chassis front, Ducati is coupling these aero changes with a new front frame that reduces lateral stiffness by 40 percent compared to the previous model, alongside a double-sided swingarm [3]. This structural modification is engineered to improve the motorcycle’s capacity to “close trajectories better,” simultaneously enhancing corner exit traction and optimizing rider feedback during acceleration [3]. This technical direction strongly suggests an industry trend towards increased chassis compliance to improve feel and mechanical grip—a factor highly relevant to the chassis experimentation underway at Bimota.

II. Bimota KB998 Rimini: Engineering the Chassis to Compensate for Engine Deficit

The 2026 development mandate for the Bimota by KRT team is one of defensive innovation. The objective is to leverage the bespoke Bimota chassis architecture (KB998 Rimini) to strategically mitigate the regulatory limitations imposed by the engine platform derived from the Kawasaki Ninja ZX-10RR. This strategy focuses on maximizing corner speed and agility as the primary countermeasure against superior straight-line performance from rivals.

II. A. Technical Diagnosis: The Power and Drag Conflict

The KB998 achieved a successful debut in 2025, securing four podium finishes, primarily in the capable hands of Alex Lowes [4, 5]. However, analysis of the bike’s performance throughout the season highlighted a critical conflict between engine output and aerodynamic profile.

The powerplant, which shares its core design with the Kawasaki ZX-10RR, is inherently down on outright horsepower when compared to the dominant engines used by Ducati, Honda, and BMW [4]. This engine deficit is exacerbated by the KB998’s aerodynamic package. The motorcycle features a distinctive fairing with a “more radical aerodynamic setup” utilizing front wings, which inherently results in a larger drag coefficient than the motorcycle it succeeded [4, 6]. The combination of lower maximum power output and higher aerodynamic drag results in a significant loss of straight-line speed, which became the KB998’s single greatest performance constraint.

Team Manager Guim Roda confirmed that the team is in a continuous struggle with the limitations imposed by mass-production rules in the engine department [4]. Rider Alex Lowes explicitly identified this as the key winter R&D priority, noting, “We still need to focus on this area during the winter… Maximise our potential in the straights is what we have to try to do for next year,” while acknowledging the restrictive nature of World Superbike regulations in this area [6]. The development solution cannot be a massive engine overhaul, which requires a long and expensive manufacturer investment; rather, it must be an optimization of existing components and fine-tuning of the bike’s overall speed profile [4].

II. B. Alex Lowes’ Development Feedback and the “Extreme Chassis Direction”

Given the constraints on engine modification, Bimota’s R&D strategy for 2026 focuses heavily on exploiting chassis geometry, kinematics, and suspension to find performance gains. The initial post-season testing at Jerez saw the team explore substantial alterations to the bike’s dynamics.

Alex Lowes and the Bimota KRT technical staff implemented a “more extreme chassis direction,” incorporating a specialized, different swingarm and new components supplied by Showa [6]. These modifications represent fundamental changes to the bike’s handling characteristics—changes that could not be risked during the intense pressure of the 2025 racing season [6].

Lowes’ subjective feedback from these tests was crucial. He reported finding “good benefits” and noted that the extreme direction made the KB998 “a bit easier to ride.” He specifically cited improvements in managing the bike when “stopping the bike and changing direction from [turn] two to three to four,” with clear performance gains observed in “especially sector one” of the Jerez circuit [6]. Jerez’s Sector 1 is characterized by sequences demanding hard braking and rapid changes of inertia. The noted improvements indicate that the new chassis configuration, likely involving adjustments to rake, trail, and the stiffness profiles of both the main frame and the swingarm, successfully optimizes agility and minimizes the energy expenditure required to transition the bike from full lean to maximum braking effort.

The underlying mechanism here is the maximization of corner speed. By improving the bike’s capability to brake later and carry higher velocity through the mid-corner phase, the team successfully shortens the length of the straight where the engine deficit is most pronounced. Lowes’ feedback confirms that faster corner speed and enhanced corner exit acceleration are the team’s only reliable technical countermeasures to the existing lack of straight-line power. Team Manager Guim Roda encapsulated this holistic approach, confirming the off-season work targets “the speed on the straights, the aerodynamics and the suspension” [7].

II. C. Strategic Engine Improvement Path via Concessions

While limited in the scope of raw power upgrades, Bimota must strategically utilize the FIM’s concession system to maximize the output and efficiency of the Kawasaki-derived engine. The cost and timeline associated with an entirely new mass-production engine from Kawasaki are prohibitive, forcing Bimota to rely on the more flexible engine tuning options provided under the Superconcession regulations [4].

Roda indicated that the development path must focus on the “Superconcession possibilities and concessions” to achieve the necessary technical step forward [5]. This suggests that Bimota’s engine development will prioritize refinement of the torque curve and optimization of power delivery, rather than achieving a high, but potentially unusable, peak horsepower figure. The focus will be on maximizing the efficiency of the engine in the low-to-mid RPM range, which is essential for rapid corner exit acceleration and traction—the exact points where the refined chassis setup will translate mechanical grip into speed. The strict regulatory requirement to nominate and introduce these Superconcession parts early in the 2026 season [1] necessitates that the team validates these specific tuning modifications with high confidence during the remaining winter test program.

III. BMW Motorrad Motorsport: Redefining the M 1000 RR Platform

BMW Motorrad Motorsport approaches the 2026 season facing distinct challenges driven by a post-championship regulatory reset and a complete restructure of its factory rider lineup. The development task is centered on re-optimizing the M 1000 RR platform following the revocation of key concessions and ensuring the machine’s dynamic properties are adaptable to incoming riders, Miguel Oliveira and Danilo Petrucci [8].

III. A. Post-Concession Challenges and the 2025 Technical Reset

A major technical setback for BMW entering the 2025 season—and a foundational factor influencing 2026 R&D—was the forced abandonment of the specialized 2024 Superconcession M 1000 RR chassis. After winning the Riders’ Championship, the performance balancing mechanism of WorldSBK required BMW to revert to the standard production chassis specification [9, 10].

The previously deployed Superconcession chassis was described by BMW Motorrad Motorsport Technical Director Christian Gonschor as having a “dedicated distribution of torsion and lateral stiffness” developed over several years of rider data acquisition [9]. This specialized frame was engineered to perfectly suit the aggressive, front-heavy riding style of their leading rider, enhancing late braking performance and allowing the bike to maintain a more consistent line through corner exits [9]. The mandated reversion to the production frame meant the team had to return to the drawing board to address new handling deficiencies, particularly the loss of optimal rear grip in elevated temperatures, which caused palpable frustration during the 2025 campaign [11]. The 2026 development must seek to bridge this kinematic performance gap using revised suspension and electronic strategies, as the specialized chassis structure is no longer available.

Furthermore, BMW, like other manufacturers whose performance is subject to balancing measures, has contended with regulatory limits on fuel flow. Technical Director Gonschor categorized the progressive reduction in fuel flow as “no small matter” [12]. The restriction limits the total volume of fuel available to the engine per unit of time, thereby constraining peak engine power—a factor that riders reportedly feel acutely. Michael van der Mark emphasized that “We feel every reduction,” noting that reducing the fuel flow directly decreases engine power, which diminishes the enjoyment and competitive potential of the machine [12]. This mandated power cap means that BMW’s 2026 development must focus on achieving maximal mechanical and aerodynamic efficiency (less drag) to counter the regulation-induced loss of engine performance.

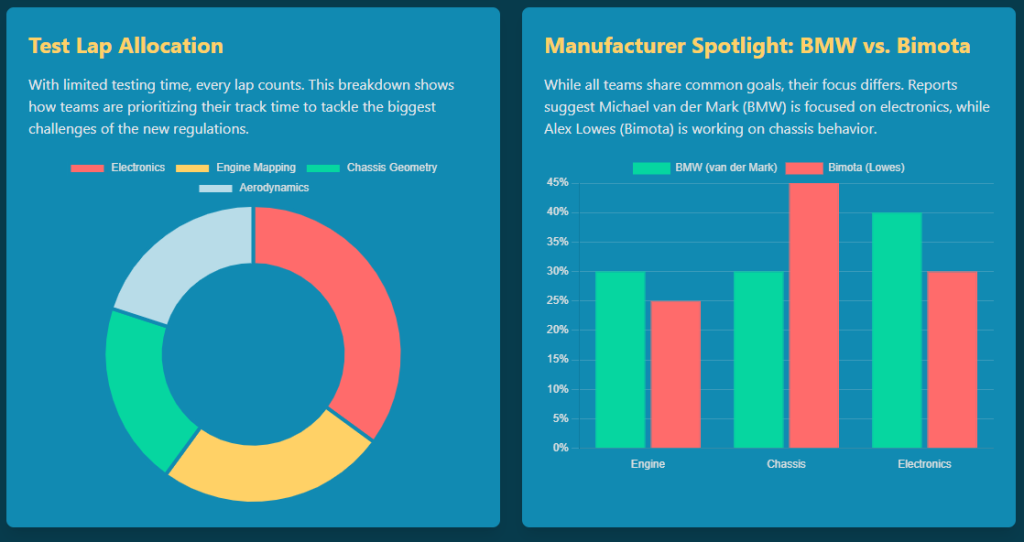

III. B. Michael van der Mark’s Strategic Transition and Test Mandate

The most significant strategic move for BMW in preparing for 2026 is the transition of Michael van der Mark from a full-time factory rider to a dedicated test rider [8, 13]. This change reflects BMW’s recognition that a highly experienced and fast development rider is essential to rapidly validate new technical directions.

Van der Mark’s tenure since 2021 provides him with invaluable institutional knowledge regarding the M 1000 RR’s evolving architecture [14]. His new mandate is explicitly to “improve the package” for the two incoming high-profile factory riders, Miguel Oliveira and Danilo Petrucci [8]. The core challenge for BMW is developing a competitive platform that offers a wide and predictable operational window, catering to the distinct riding styles of two individuals transitioning from different competitive environments. Oliveira arrives from the highly prototype-focused MotoGP environment, while Petrucci brings extensive experience on various WorldSBK-spec machines [8].

Van der Mark has already commenced this critical work, undertaking tests where the team experimented with “a lot of different setups” [13]. These sessions are dedicated to testing radical settings and components that are too risky to implement during a standard race weekend. The goal is to compress the R&D cycle by rapidly validating fundamental chassis kinematics and electronic interaction strategies. His deep understanding of the M 1000 RR’s inherent stiffness profile makes him the ideal asset to help the team define a reliable performance baseline for the production-spec chassis, mitigating the performance regression experienced after the loss of the Superconcession frame.

III. C. Kinematics Refinement and Electronic Compensation for 2026

The technical direction for the 2026 M 1000 RR is defined by two interlocking pillars: chassis kinematics refinement and advanced electronic tuning.

As the bespoke Superconcession frame is unavailable, development centers on optimizing the standard production frame through meticulous tuning of the suspension geometry and kinematic components. BMW engineering emphasizes “even greater chassis performance” through adjusted kinematics, leveraging the standard M 1000 RR’s advanced features, including the short engine with BMW ShiftCam technology [15]. The objective is to refine the balance between torsional and lateral stiffness distribution within the production chassis to regain the critical front-end feel and rear traction that were previously optimized by the Superconcession chassis [9]. The ability to restore rider confidence under heavy braking and cornering relies entirely on achieving this difficult kinematic balance.

Concurrently, the engine management system must be rigorously optimized to compensate for the mandated fuel flow restrictions [12]. BMW possesses a highly sophisticated electronics suite, featuring seven riding modes, two adjustable throttle characteristics, ABS Pro, Dynamic Traction Control (DTC), and a triple-adjustable engine drag torque control system [15]. Given the inability to significantly increase engine power due to regulatory caps, the strategic focus shifts to maximizing the usability of the available torque. Precise electronic management—particularly refining the ShiftCam engagement profile and optimizing the engine drag torque system—is critical. This allows the incoming riders, Oliveira and Petrucci, to replicate the aggressive corner entry speed previously achieved by the previous champion, even with a technically constrained engine and chassis configuration.

IV. Comparative Development Analysis

The 2026 development programs of Bimota and BMW highlight two distinct engineering philosophies driven by their specific regulatory and technical constraints. Bimota engages in defensive engineering, focused on overcoming a power deficit through chassis supremacy, while BMW is engaged in offensive re-optimization, seeking to regain a technical edge lost to regulation changes and adapting the platform for a new team composition.

The reliance of both teams on Superconcessions necessitates precise and early decision-making. The rule requiring the nomination and full introduction of earned Superconcession parts early in the 2026 season [1] dictates that the crucial winter testing period must yield unequivocal data, minimizing the risk of a sub-optimal component setting the performance baseline for the year.

IV. A. Technical Development Matrix: Bimota vs. BMW Priorities

The following table summarizes the divergent strategic allocation of R&D resources for the 2026 WorldSBK campaign.

FIM Technical Regulation Changes and 2026 Development Impact

| Regulation Area | 2026 FIM Change/Clarification | Strategic Impact on Bimota Development | Strategic Impact on BMW Development |

| Superconcessions Token Use | Parts earned at season end must be introduced before further tokens are earned [1]. | Forces early nomination of critical engine tuning upgrades (torque/acceleration focus); restricts in-season flexibility. | Requires immediate validation of chassis or engine components; increases dependence on accurate winter test data correlation. |

| Aerodynamic Devices Compliance | Maximum deflection of 10 mm under a 50 N vertical load [2]. | Must re-engineer ‘radical’ aero package to be stiffer and reduce drag coefficient [6]; may introduce weight or complexity. | Aero design must ensure rigidity without adding unnecessary bulk, offsetting mandated power loss from fuel restrictions [12]. |

| Testing Restrictions | Restriction established to reduce overall development costs [2]. | Places high value on efficient data extraction from limited sessions, prioritizing chassis/suspension tuning consistency [7]. | Confirms the strategic value of Michael van der Mark’s dedicated, highly experienced test rider role [8]. |

IV. B. Bimota KB998 Rimini: Chassis Innovation to Counter Regulation-Induced Deficit

Bimota’s core risk lies in whether the “extreme chassis direction” tested by Alex Lowes provides sufficient advantage in corner speed and braking stability to consistently negate the speed differential faced on straights against powerhouses like Ducati, Honda, and BMW. The gains reported by Lowes in technical sections, specifically Sector 1 of Jerez, indicate successful optimization of the bike’s behavior under heavy load and rapid transitions [6]. These performance gains are directly attributable to changes in frame and swingarm stiffness characteristics, aimed at maximizing mechanical grip and feel during acceleration phases—the key to carrying higher exit speed onto the straights.

Bimota KB998 Rimini – 2026 Development Focus and Lowes’ Feedback

| Targeted Area | 2025 Performance Constraint | 2026 Test Items/Feedback (Jerez) | Primary Technical Objective for 2026 |

| Straight-Line Speed | Outright power deficit coupled with high aerodynamic drag [4, 6]. | Lowes focused on maximizing potential on straights and improving acceleration [6]. | Utilize Superconcessions for flexible engine tuning (torque delivery) and optimize aero for lower drag/higher speed [5]. |

| Chassis Agility & Direction Change | Requires significant setup changes not possible during the season [6]. | “More extreme chassis direction,” different swingarm, new Showa components [6]. | Enhance braking stability and change of direction speed to minimize time loss in technical sectors (Lowes noted benefits in Sector 1) [6]. |

| Corner Exit Traction | Necessity to maximize drive onto straights to counter speed deficit [6]. | New swingarm design (potentially altering pivot point or rigidity characteristics) [6]. | Improve mechanical grip and rider feel upon acceleration through refined rear suspension kinematics [7]. |

For Bimota, the technical recommendation must emphasize the imperative to achieve iterative, measured adjustments to the fairing profile. The goal is to successfully reduce the drag coefficient without compromising the enhanced downforce characteristics, all while strictly adhering to the FIM’s new 10mm deflection limit [2, 6]. The high-agility chassis improvements will be inherently limited if the fundamental aerodynamic impediment to straight-line acceleration remains unaddressed.

IV. C. BMW M 1000 RR: Re-Optimization Post-Concession Loss and Rider Transition

BMW’s risk profile for 2026 is linked to the speed and effectiveness of their technical transition. The major constraint is the necessary adaptation to the production-spec chassis, which lacks the bespoke stiffness distribution tailored for the previous champion [9]. The entire transition hinges on the highly experienced Michael van der Mark successfully mapping the M 1000 RR’s performance envelope for the incoming riders in a limited testing window [2, 8].

BMW M 1000 RR – 2026 Technical Priorities and Rider Transition

| Development Phase | Constraint or Challenge | 2026 Strategic Solution (Van der Mark Focus) | Expected Technical Result / Metric Focus |

| Chassis Baseline Definition | Loss of specialized 2024 Superconcession chassis stiffness distribution [9]. | Van der Mark testing “a lot of different setups” to find a new flexible baseline [13]. | Restore confidence in braking/mid-corner, and address persistent rear grip issues in high temperatures [11]. |

| Rider Adaptation | Preparing the package for new, high-profile riders (Oliveira, Petrucci) [8]. | Dedicated, experienced testing to define broad optimal operating window for chassis/electronics [8]. | Minimize adaptation time for incoming riders; ensure platform stability and predictability across varying track conditions. |

| Engine Management/Efficiency | Progressive fuel flow restrictions impacting power output [12]. | Focus on electronic tuning (ShiftCam, DTC, Engine Drag Torque) to maximize usable torque [15]. | Maintain competitive acceleration and power delivery despite regulatory caps, optimizing efficiency within the FIM fuel limit. |

The key technical recommendation for BMW centers on data-driven kinematics simulation and advanced electronic compensation. Given the difficulty in structurally modifying the homologated production frame, the R&D team must leverage van der Mark’s feedback and telemetric data to develop refined electronic strategies (throttle maps, DTC, and engine brake management) that actively compensate for the inherent differences in torsional stiffness compared to the lost Superconcession unit [9, 15]. The electronics must serve as the primary bridge, ensuring predictable handling and consistent rear grip for the new riders under varying loads and track temperatures.

V. Conclusions and Strategic Outlook

The 2026 WorldSBK development cycle is characterized by intensely focused, constraint-driven R&D programs at both Bimota and BMW.

Bimota by KRT is committed to a specialized strategy where chassis excellence must fundamentally override a regulatory-induced power deficit. The immediate success reported by Alex Lowes on the “extreme chassis direction” confirms the validity of this approach, emphasizing high corner speed and agility as the path to competitiveness. However, Bimota’s overall success depends on achieving a secondary breakthrough in aerodynamic efficiency to address the high drag coefficient currently nullifying the Kawasaki engine’s potential on straights.

BMW Motorrad Motorsport faces the unique challenge of re-establishing a technical baseline following the revocation of its title-winning chassis advantage and simultaneously preparing a stable platform for two new factory riders. The strategic deployment of Michael van der Mark as a dedicated, experienced test rider is critical to compressing the adaptation period for Oliveira and Petrucci. BMW’s R&D must focus on electronic tuning—leveraging sophisticated systems like the triple-adjustable engine drag torque control—to manage the constrained power output due to fuel flow caps and stabilize the handling characteristics of the production chassis.

The competitive landscape for 2026 is poised to escalate, driven by Ducati’s adoption of ground-effect aerodynamics and reduced lateral chassis stiffness [3]. Both Bimota and BMW must successfully execute their respective, divergent development strategies during the winter break. Given the FIM’s stringent rule regarding the early nomination of concession parts, the efficiency and accuracy of data collection during the limited testing schedule will prove decisive in determining competitive parity throughout the crucial opening rounds of the 2026 season.

Our Social Media Handles

- Instagram : LivingWithGravity

- Medium : Akash Dolas

- YouTube Channel : Gear and Shutter

- Facebook : LivingWithGravity